0

HARRISON SPINKS

The true bedmakers

WE ARE THE SLEEP TAILORS

We love sleep. It keeps us healthy and makes us happy. It has the power to restore us and make us feel human again. Sleep is special, so we don’t think it should come off the shelf - we think it should be tailored to you.

That’s why at Harrison, we don’t just make beds. We make a great night’s sleep.

ONE PERFECT SLEEPING SURFACE

So confident are we about the performance of our springs, that we are able to make a mattress that doesn't need turning. Sumptuous natural fillings are carefully layered above our innovative spring systems to provide targeted support close to the mattress core. This unique design offers all the luxurious comfort you'd expect from a Harrison bed without the back-breaking work of turning the mattress over.

WE GROW BEDS

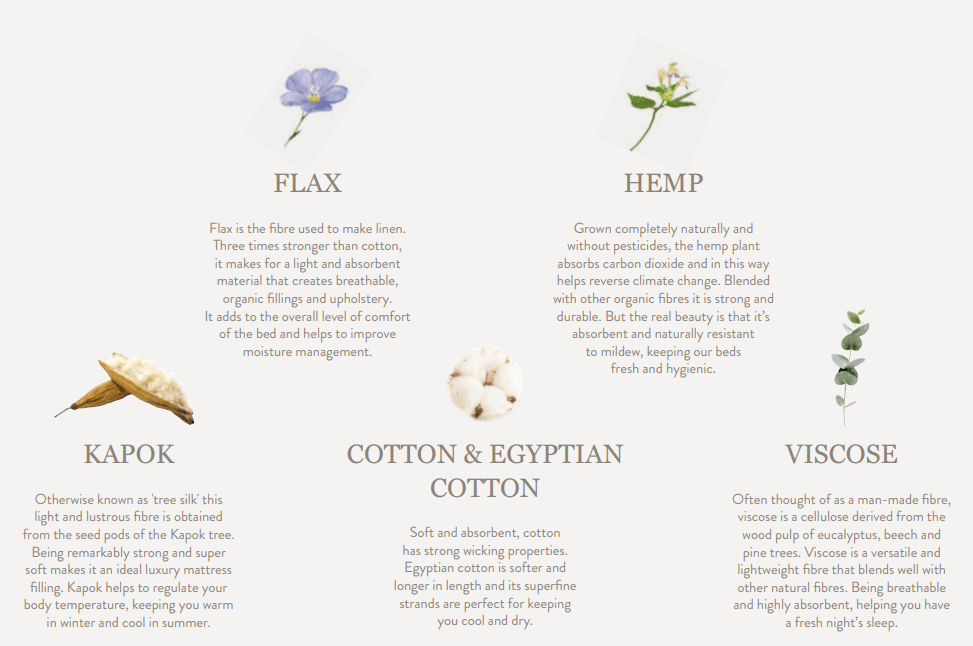

Your bed doesn’t start out life in a factory, but on a farm. A 300 acre farm in North Yorkshire to be precise. Here we rear sheep for their wool and produce the natural fibres that go into our fillings. Fibres like flax that is three times stronger than cotton, with unique properties that help keep you cool and fresh.

This is also where we grow our hemp, a carbon-neutral fibre that’s carefully nurtured without the use of pesticides.

We don’t do this because it’s easier. (It takes us a year to grow the ingredients for one mattress.) We do it because we believe in sustainable manufacturing. And because, with over 100 years of experience, we’ve learned that if you’re going to make a beautiful bed, you’ve got to do it yourself.

CASHMERE

SOFTER AND STRONGER

The double coat of the cashmere goat is both soft and smooth, but also highly resilient. While the outer layer is durable, the fine, soft underdown is lighter and more insulating than other wools.

MOHAIR

THE FINEST OF TEXTURES

Softer and smoother than wool, mohair's fine silky texture gives it a more luxurious feel and is used in the warm side filling layers of the mattress. Its strong, light and soft fibres share the beneficial properties of wool but with added sumptuousness.

SHEEP'S WOOL

HOME-GROWN SOFTNESS

Soft, springy and naturally supportive. Wool keeps you warm and dry and helps regulate body temperature. It’s also anti-bacterial and, as it’s inherently fire-retardant, there’s no need to use chemicals in any of the fillings. We raise our own sheep, making it more sustainable.

SILK

LUXURY MEETS STRENGTH

Silk is a luxurious protein fibre found in our very best beds. Produced by the mulberry silkworm, it’s also the strongest of the natural fibres. Silk has natural moisture absorbing qualities making it perfect for regulating body temperature.

ALPACA

NATURALLY HYPOALLERGENIC

Known for its softness, alpaca wool is inherently softer and warmer than sheep’s wool. This luxuriously soft yet durable fibre has the luster of silk and due to containing no lanolin is naturally hypoallergenic, with excellent moisture wicking properties.

LORD OF THE MANOR

Meet Harrison. He is just one of the prize sheep you’ll find at our farm. Reared on the lush grass of our farm, he obliges us with the luxurious wool that goes into all of our beds. Wool, king of all fibres, is inherently fire retardant, ensuring no chemicals are used in the fillings. It also naturally regulates body temperature, keeping you comfortable throughout the year.

We love natural fibres, not only are they more sustainable, but they also have a number of unique properties unlike any man-made fibre. Ensure your bed is fit for a king and speak to one of our bed experts to find the right bed for you

BRINGING WEAVING BACK TO YORKSHIRE

In line with our ethos to be the world’s most vertically integrated bed manufacturer, we not only grow our own natural fillings and draw our own wire, we also weave our own mattress ticking.

Here at our factory we combine traditional methods with state-of-the-art weaving looms to create naturally breathable fabrics for the sleeping surface.

Previously manufacturers have added chemicals to the surface of fabrics making them fire retardant. Our high quality woven fabric has a Chem-free finish. Using materials that boast inherently fire

retardant properties. The fabric is then steamed finished, meaning no other chemical treatments are required. An innovative but natural finish to the perfect night’s sleep.

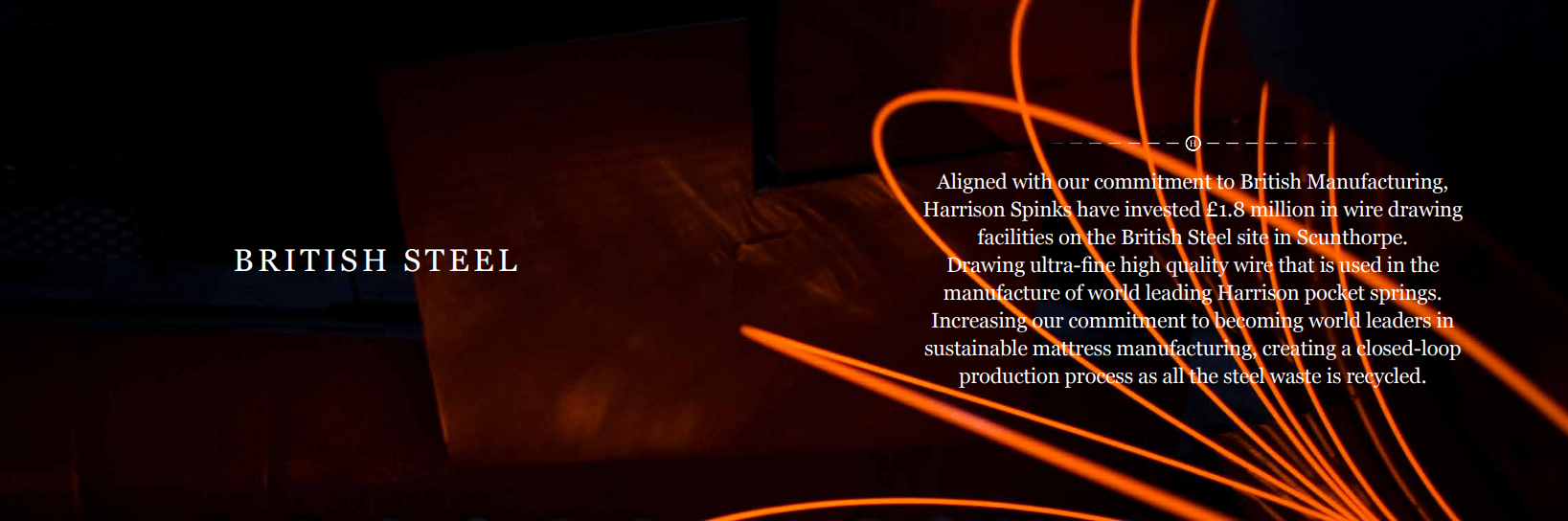

SPRING TECHNOLOGY

Inside every bed we make, there are several thousand miracles of engineering at work. Precision made springs-within-springs and high-density pocket springs made with titanium alloy wire. It’s the most innovative support technology you’ll find anywhere in the world. Technology that makes every night’s sleep the best you’ve ever had.

IT’S NOT JUST A SPRING, IT’S A REVOLUTION

Introducing the award-winning Revolution spring. A unique system with a small spring sitting inside a larger one, offering two levels of firmness and adding to the life and performance of your mattress. Its two-stage action means the outer spring offers a high degree of comfort, while the inner spring then delivers a supportive second action. This gives you variable levels of support, tailoring itself to your unique shape so you always maintain the best posture. It’s one spring that gives twice the comfort.

---------------------STAGE 1

In the first stage of the action, the outer spring offers a high degree of comfort for lighter areas of the body, such as your legs.

---------------------STAGE 2

The second stage offers a more supportive action, and enhances the level of comfort for areas of the body that absorb the most pressure during sleep, such as the shoulders and hips.

MICROLUTION

Representing the latest in mattress spring technology. These small and supremely resilient springs are comprised of a tall mini-spring enclosed within a High Density (HD) spring. Contouring to your body, the thousands of springs in each layer keep your spine in alignment and help to reduce pressure points.

A truly revolutionary advanced spring system with up to 5000 springs in one layer, the composition of the springs means they retain their height and work against the settlement of your mattress fillings.

HD AIRFLOW

Airflow does exactly what its name suggests, channelling air through the mattress fillings and directing it to the surface. This, along with special air vents, helps the mattress to breathe, keeping the fibres fresh and dry whatever the season.

The HD is a world first. Made with our lightweight titanium alloy, these springs are highly flexible, working completely independently of each other.

The three-dimensional support means they can adapt to your body's contours to relieve pressure and give greater comfort and lumbar support. They are also good for the mattress itself as they ensure the fillings always push back to their original position.

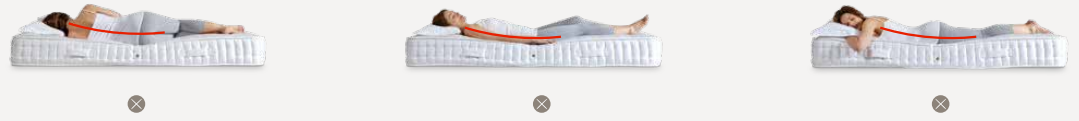

THE BACKBONE OF GOOD HEALTH

Whether you are standing up or lying down your spine always needs to be aligned. This is because a straight spine puts less strain on your hips and shoulders.

Since no two spines are the same, Harrison beds are tailored to you and adapt to the contours of your body. This helps keep your spine aligned no matter what your sleeping position.

To suit the needs of you and your partner, we can even tailor each side of the same mattress to a different Level of firmness.

That’s why they call us The Sleep Tailors.

WHEN WE ARE LYING DOWN,

IDEAL POSTURE CAN ONLY BE

ACHIEVED WHEN THE 33 BONES

IN OUR SPINAL COLUMN ARE

PERFECTLY ALIGNED. CORRECT

POSTURE IS THE KEY TO A GOOD

NIGHT’S SLEEP.

JUST RIGHT

When a mattress is just right for you it works with you and supports your body evenly. This alleviates any pressure and keeps your spine perfectly aligned.

TOO SOFT

When a mattress is too soft for you it can put severe pressure on your lower back. It is not only uncomfortable, it can cause stiffness the following day.

TOO FIRM

When a mattress is too firm for you it can create pressure around the shoulders, hips and the knees, causing a restless night.

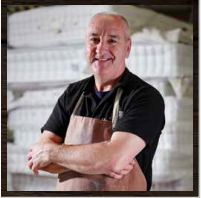

MEET OUR MACHINERY

In tailor-making a Harrison bed, our most valuable tools are our hands. But these are not just any hands. They belong to craftsmen like Andy Davis. In one week Andy will stitch our

unique beds using a 16-inch needle and a lot of patience.

After doing this for over 25 years he’s got it down to a fine art. An art that a machine will never be able to master.

Andy Davis

Harrison Spinks side-stitching Specialist

© 2024. The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.